Uncategorized

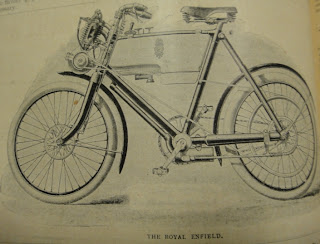

1901 Enfield Detailed Specifications

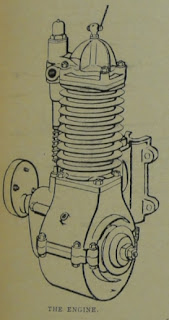

“The engine, as will be noticed, is of an extremely robust form, and is provided with ample wearing surfaces. The power at full speed is 1.75hp; the timing gear wheels are enclosed in a special outside case, and both axles have good long bearings, whit phosphor bronze bushes.

The contact breaker plate has a bush fitting over an extension of the aluminum chamber; this bush is of large diameter, and about 0.75 inch wide. There is, therefore, no chance of the plate developing side play through wear, and upsetting the accuracy of the adjustment between cam and spring.

The makers claim that by fitting the motor in front of the head, not on the handle bar, but bolted to the frame it self, they obtain the maximum of air for cooling purposes, which is undoubtedly correct; at the same time the motor is well out of the dirt. The belt drive differs from the majority of machines which wwe have seen being V section, and run crossed instead of open. By means of the long drive, the belt can be run slacker without slipping, and the crossing causes it to encircle the small driving pulley much further.

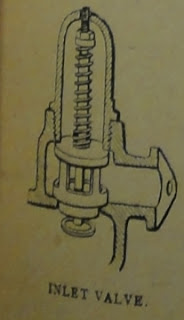

Large valves are fitted to both exhaust and inlet, the exhaust pipe being especially large and strong, terminating under bottom bracket, where a silencer of ample dimensions is firmly bolted to the bridge of the bicycle frame.

In our illustration of the inlet valve, the arrrangement for testing whether valve is free is clearly shown.

The stalk of the valve extends through the dome, and as the body of the inlet valve is provided with a special casting with two seats, air cannot be drawn in through the top of the dome. This small fitting is very useful, and often saves a great deal of time; the joint is not disturbed, and consequently lasts much longer than it otherwise would do.

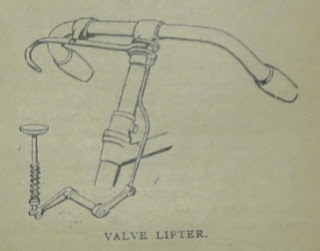

The exhaust valve is fitted with a very certain, but simple, lifter, and as the lever operating it is attached on the right handlebar, and the switch on the left, the whole command of the machine is in the rider’s hands, without leaving go of the handles.

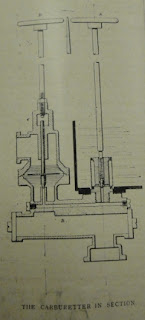

The carbuertter is quite automatic, and is entirely governed by the adjustable illed top of stalk A, referring to the illustration in section; stalk marked A terminates in needle point with a screw adjustment. This has to be opened from a quarter to half a turn; the petrol flows along the passage marked B and rises to the needle valve, which is under the stalk marked D. The height of the lift of this valve is set when the machine leaves the facotry, and need not be disturbed when running; a supply of more or less petrol will govern the carburation, and when the best position is found, a letter O is marked on the top of A when open, and the letter S when shut, these letters being opposite the needle or indicator between the two milled tops.

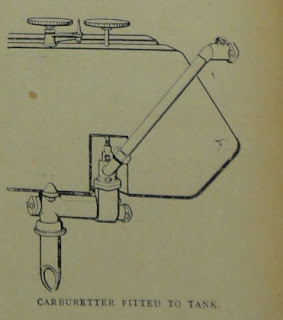

The tank to which the carburetter is attached contains one gallon of petrol, and a compartment for induction coil and accumulator.

The frame is specially made throughout, and has been designed purposely for a motor-bicycle. Special thick gauge tubing is used everywhere, and the wheel base has been considerably lengthened. The front forks are of a most substantial pattern, being made in D section, and of great strength. The crown is the same as the one used on the Royal Enfield tricycles for the last 18 months, and which has given entire satisfaction.

The brakes are two in number; both are hand brakes, one acting on the back wheel, and the other on the front. It was deemed advisable to fit two brakes, as running down a steep hill with the valve lifter raised, one brake was not found sufficient to arrest the machine suddenly, but with a gentle application of both, this machine can be stopped in a few yards in case of emergency.”